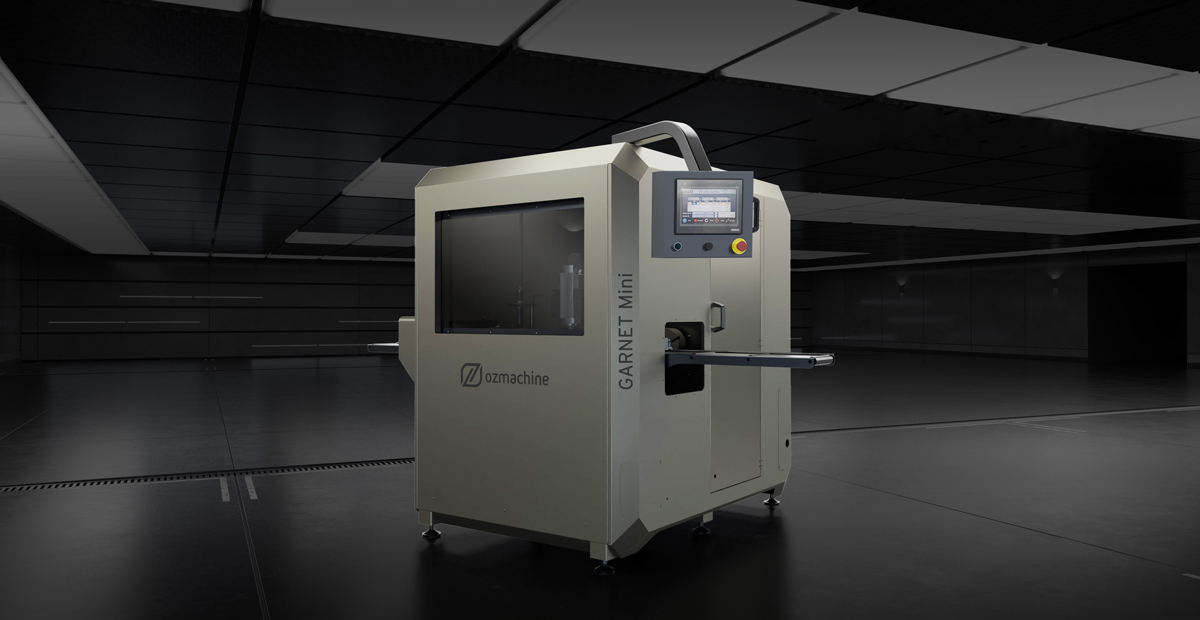

Our compact machining center, the GARNET Mini machine, is capable of catering to beginner and intermediate workshops. Thanks to its 3 standard and 1 optional spindle motors, it allows precise operations on 3 surfaces of the profile at once without lifting the profile. Thanks to the servo motors on the axes, it offers precise positioning and operation at the desired point in the process area. Thanks to its compact structure, it saves space and makes the working area more comfortable.

Our company has a long history of manufacturing aluminum and PVC machinery, dating back to the 1980s. We are constantly seeking new ways to innovate and improve our products.

We are continuously improving our aluminum machining equipment. Our product range encompasses 5-axis machines to 3-axis machines. Our primary focus is on precision machining, rigid construction, and ensuring safe and easy operation.

We offer a wide range of cutting machines to provide our customers with solutions for various aluminum and PVC cutting applications. Thanks to the precision cutting capabilities of our machines, users can achieve flawless results.

Introduction

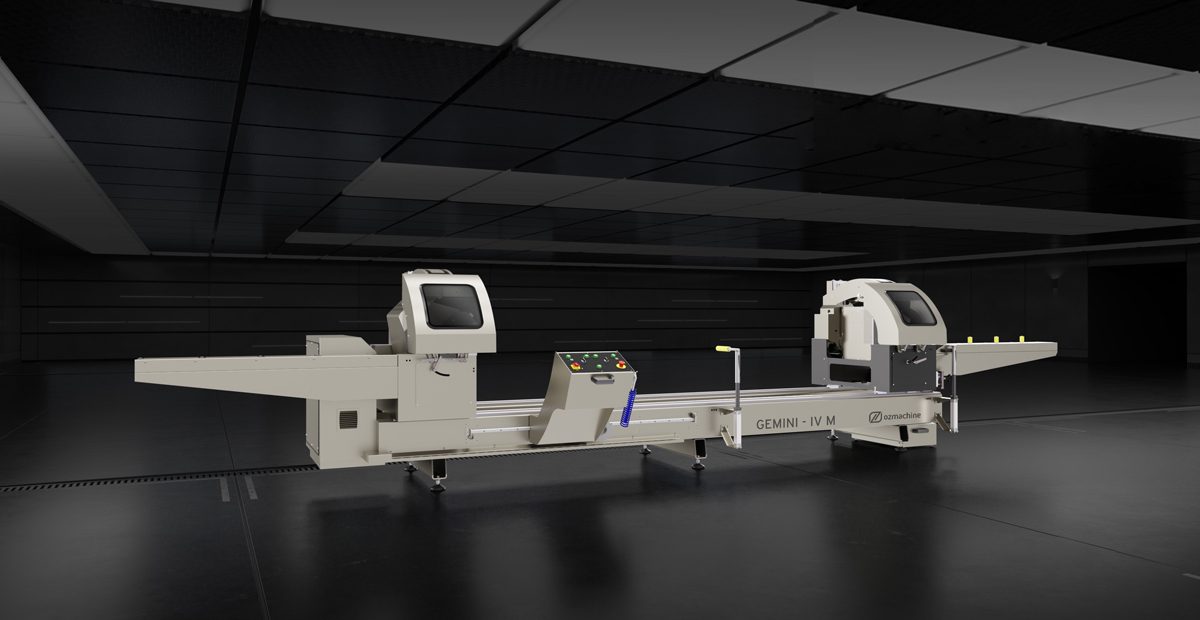

In today’s fast-paced manufacturing and fabrication industries, precision, efficiency, and ease of use are paramount. The Double Head Front Blade Saw Ø 450 mm is engineered to meet these demands with state-of-the-art features like semi-automatic angle adjustment and a digital measurement display. This cutting-edge equipment is designed for professionals who require reliability, repeatability, and razor-sharp accuracy in their daily operations.

Key Features and Benefits

1. Ø 450 mm Double Head Front Blade System

Offers a powerful and efficient cutting solution for large profiles and heavy-duty materials.

Dual-head configuration ensures symmetrical and simultaneous cutting, reducing processing time significantly.

2. Semi-Automatic Angle Adjustment

Simplifies the setup process with pre-set angle positions and easy-to-use controls.

Increases productivity while maintaining high accuracy for compound cuts and custom angles.

3. Digital Measurement Display

Provides real-time measurement feedback for precise cutting lengths.

Enhances user confidence and reduces material waste due to miscalculations or human error.

4. Built for Durability

Heavy-duty frame and components withstand intensive industrial use.

Precision-engineered for long service life and minimal maintenance.

Applications

Aluminum and PVC profile cutting

Window and door manufacturing

Furniture and modular systems

Architectural metalwork

Why It Stands Out

Unlike conventional saws, this model’s advanced semi-automatic angle adjustment saves both time and effort while the digital display ensures pinpoint precision. Whether you’re working in mass production or bespoke fabrication, this saw is a game-changer in your workshop.

Conclusion

If you’re looking to enhance your workshop’s productivity and precision, the Double Head Front Blade Saw Ø 450 mm is a must-have. With features tailored to modern manufacturing needs, it combines cutting-edge technology with user-centric design.

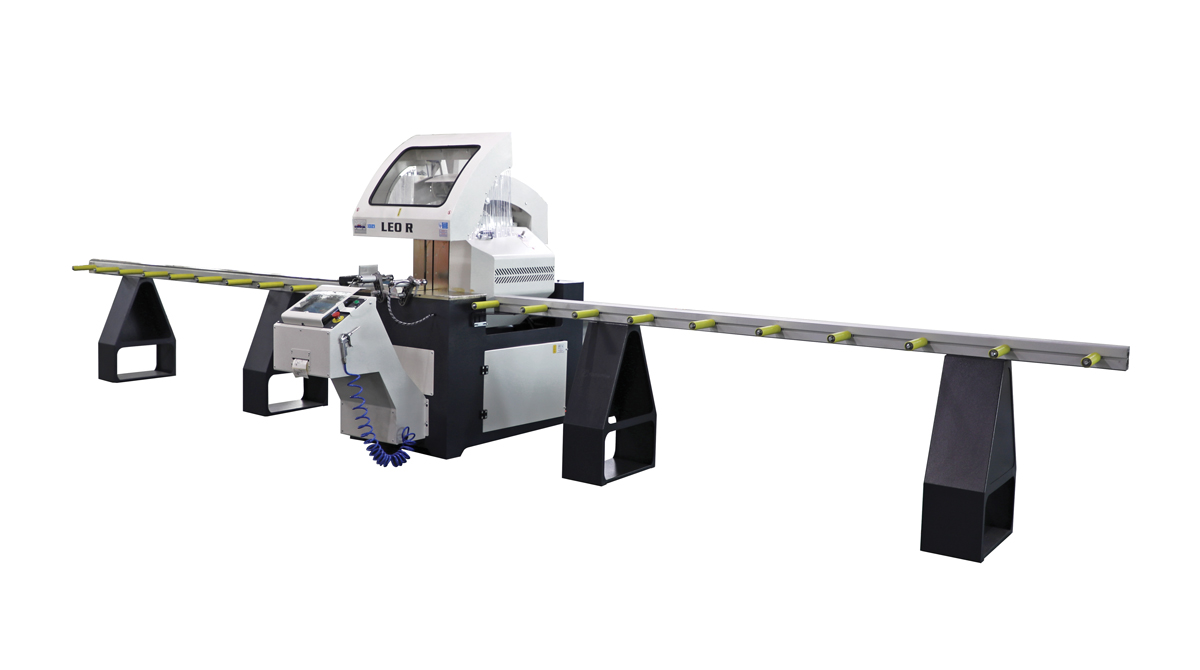

Automatic Front Blade Saw Ø 550 mm – 2 Axis Servo Controlled

Precision Cutting Meets High-Speed Automation

In the world of aluminum and PVC profile processing, time and precision are everything. The Automatic Front Blade Saw Ø 550 mm – 2 Axis Servo Controlled stands out as a robust solution that combines cutting-edge automation with high cutting capacity. Designed for high-performance production lines, this machine delivers repeatable accuracy, reduced cycle times, and minimal operator intervention.

What is an Automatic Front Blade Saw?

An Automatic Front Blade Saw is a profile cutting machine where the saw blade advances from the front of the machine—rather than from above or below—offering improved visibility and safer operation. The Ø 550 mm saw blade ensures deep and clean cuts, while the 2-axis servo control system enhances movement precision and flexibility for various cutting angles and dimensions.

Key Features

🔧 1. Large Diameter Saw Blade (Ø 550 mm)

The high-diameter circular saw blade allows for cutting of large and thick profiles with ease, making it ideal for industrial-grade applications.

⚙️ 2. 2 Servo Axis Control

Axis 1: Controls the positioning of the profile for exact cut lengths.

Axis 2: Manages the movement and entry of the saw blade for smooth, precise, and consistent cuts.

These servo axes ensure high-speed and synchronized movements, improving cycle efficiency.

📐 3. Adjustable Cutting Angles

Depending on the configuration, the machine can be programmed for straight or angle cuts, allowing for versatile production requirements.

🖥️ 4. Touch-Screen CNC Control Panel

The user-friendly interface allows easy job setup, program saving, and integration with cutting lists from external systems. Operators can manage cutting jobs quickly without specialized training.

🛡️ 5. Safety and Protection

Equipped with protective covers, emergency stop systems, and sensor-based safety features, the machine ensures operator safety without compromising productivity.

Advantages for Manufacturers

High-Speed Cutting: Servo motors enable faster positioning and cutting cycles.

Consistent Accuracy: Perfect for large-volume orders requiring precision down to the millimeter.

Reduced Labor: Automation simplifies operation—ideal for reducing workforce dependency.

Low Maintenance: Servo systems are highly reliable and reduce the need for frequent manual calibration.

Optimized Material Usage: Precise cuts help minimize waste, increasing overall efficiency.

Typical Applications

Cutting aluminum or PVC profiles for window and door manufacturing

Processing curtain wall or façade system components

Structural and industrial profile cutting

Preparation of profiles for further CNC machining or assembly

Final Words

The Automatic Front Blade Saw Ø 550 mm – 2 Axis Servo Controlled is a powerful asset for any profile processing facility looking to enhance speed, safety, and precision in cutting operations. Whether part of a fully automated line or used as a standalone unit, this machine represents a smart investment in modern production technology.

CNC Profile Machining Center (3+1 Axis)

High-Performance Machining for Aluminum and PVC Profiles

The CNC Profile Machining Center (3+1 Axis) is a next-generation solution designed for precision machining of aluminum and PVC profiles. Combining speed, flexibility, and digital control, this machine offers exceptional performance for manufacturers who demand accuracy and efficiency in every operation.

What Does “3+1 Axis” Mean?

The 3+1 axis configuration provides three main linear motion axes (X, Y, Z) and an additional rotational axis that enables profile machining at multiple angles. This design allows the system to perform complex operations — such as milling, drilling, slotting, and end machining — without the need for manual repositioning.

The result is faster production, higher accuracy, and consistent quality, even for the most demanding profile shapes.

Main Features

3 Linear + 1 Rotational Axis Control: Ensures precise and efficient machining from different angles.

Servo Motor Drive System: Provides high-speed and smooth axis movement for perfect cutting accuracy.

Automatic Tool Change System: Reduces setup time and increases productivity in multi-step operations.

Strong and Rigid Frame: Prevents vibration for clean, smooth surface finishes.

Advanced CNC Control Interface: Simple programming, memory for multiple profiles, and real-time monitoring.

Optional Cooling and Lubrication System: Extends tool life and enhances machining quality.

Applications

The CNC Profile Machining Center (3+1 Axis) is ideal for:

Aluminum and PVC window and door manufacturing

Curtain wall and façade systems

Industrial profiles and structural components

Furniture and architectural profile production

Advantages of 3+1 Axis Technology

Increased Machining Flexibility: Allows angled and multi-side operations in a single setup.

Improved Efficiency: Automated tool changes and optimized cutting paths minimize downtime.

Consistent Accuracy: Servo-controlled movement ensures repeatable results for every part.

User-Friendly Operation: Simplified programming and diagnostic tools for operators of all levels.

Reduced Material Waste: Precision control leads to cleaner cuts and minimal rework.

Boost Productivity with Intelligent CNC Control

Thanks to its intelligent automation system, the 3+1 Axis CNC Machining Center integrates seamlessly into modern production lines. It ensures continuous, error-free operation, helping manufacturers meet increasing market demands while maintaining top-tier quality standards.

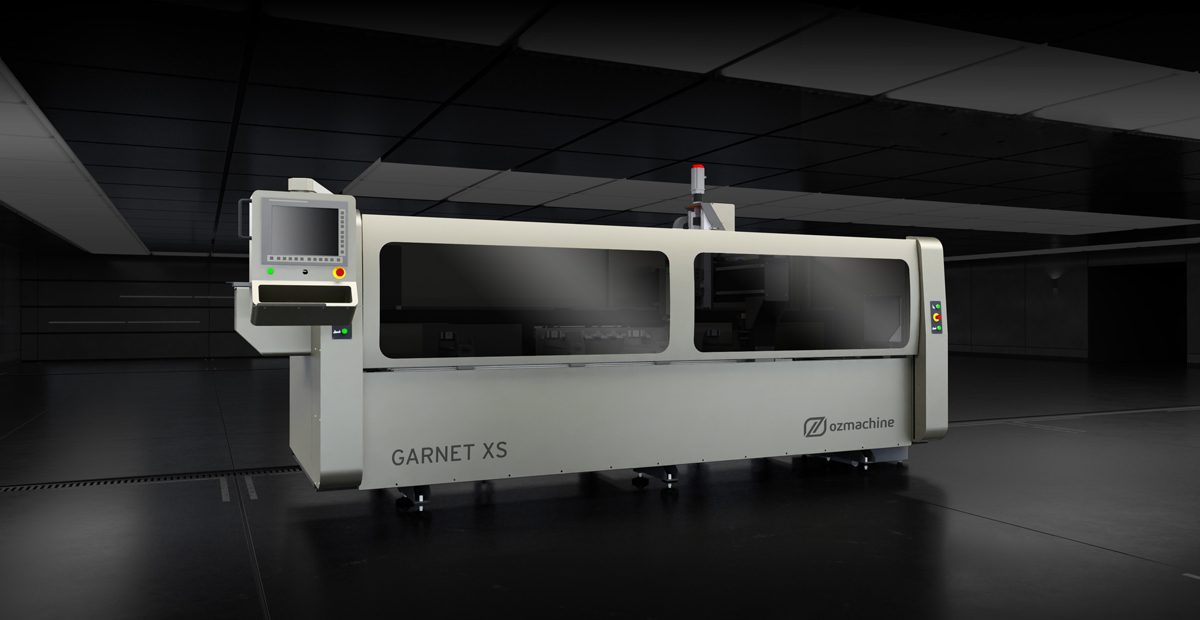

Automatic Rising Blade Saw Profile Slicing Machine with Tapping Feature Ø 500 mm

Meta Title:

High-Performance Automatic Rising Blade Saw with Tapping Option | Ø 500 mm Profile Slicing Machine

Meta Description:

Boost efficiency with the Automatic Rising Blade Saw Profile Slicing Machine Ø 500 mm featuring a tapping function. Precision cutting and threading for aluminum and PVC profiles.

Innovation That Redefines Precision

In modern production environments, speed, precision, and automation are essential. The Automatic Rising Blade Saw Profile Slicing Machine with Tapping Feature Ø 500 mm is designed to meet the most demanding requirements in aluminum and PVC profile processing.

Combining advanced cutting technology with integrated tapping functionality, this system enables manufacturers to achieve perfectly cut and threaded profiles — all in one operation.

Efficient and Accurate Cutting

At the heart of this machine is a Ø 500 mm high-speed circular blade that delivers clean, burr-free cuts.

The rising blade system ensures smooth entry into the material, minimizing deformation and guaranteeing a superior surface finish.

This makes it ideal for precision manufacturing in industries such as doors, windows, curtain walls, and industrial framing systems.

Integrated Tapping Feature

What sets this model apart is its automatic tapping function.

After slicing the profile, the machine performs precise tapping operations without the need for repositioning or manual intervention.

This integration not only improves accuracy but also reduces production time and increases overall workflow efficiency.

Key Advantages

⚙️ Dual Functionality: Cutting and tapping in a single automated cycle.

🔩 Precision Threading: Ensures accurate and consistent tapping on each profile.

🧠 CNC-Controlled System: Provides stable operation and repeatable results.

⚡ High Efficiency: Reduces setup and machining times significantly.

🪶 Smooth Rising Blade Movement: Extends blade life and enhances cut quality.

🧰 Safety and Durability: Rigid frame construction and protective covers for operator safety.

User-Friendly and Reliable

The intuitive control interface allows operators to easily set cutting parameters, blade speed, and tapping sequences.

Automatic clamping systems secure the profile firmly in place, ensuring consistent accuracy and operator safety during every cycle.

Built from high-quality industrial components, the machine is designed for continuous use, making it a reliable choice for both small workshops and large-scale production lines.

Applications

This cutting and tapping system is widely used in:

Aluminum and PVC profile production

Door and window frame manufacturing

Industrial extrusion and modular systems

Architectural and façade projects

Whether for mass production or custom fabrication, it guarantees exceptional precision and repeatability.

Why Choose This Machine?

By integrating cutting and tapping operations, manufacturers eliminate unnecessary handling and improve productivity by up to 30–40%.

Its intelligent automation system ensures flawless results, reduced waste, and consistent quality for every project.

If you’re aiming to modernize your production line, the Automatic Rising Blade Saw Profile Slicing Machine with Tapping Feature Ø 500 mm is the smart investment that delivers both performance and profitability.